PRINCE2® Foundation v7

online course and official exam

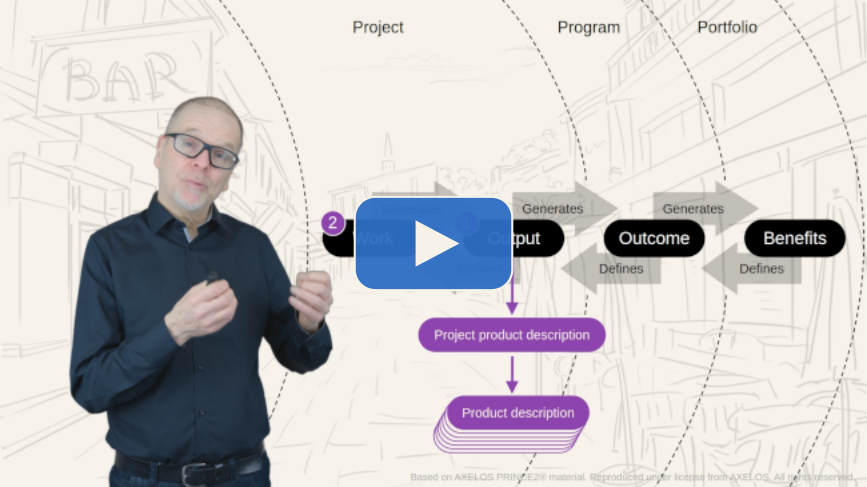

Learn PRINCE2 from one of the best-known PRINCE2 trainers, Frank Turley. This is what the course looks like:

This course offers everything you need to learn PRINCE2 and prepare for the PRINCE2 Foundation v7 exam.

We've started offering a split payment plan. Contact support if you're interested in using this option.

One year access / Exam fee included

What's included?

This package contains the official exam voucher, as well as everything you need to learn the topic and get prepared for the exam, including:Accredited by

PeopleCert

Fully aligned with the 7th edition of PRINCE2

Equivalent to a

3-Day Course

24 Contact Hours

(PDUs)

Contains

89 Lessons

Exam Simulator with

365 Questions

With 2

Sample Exams

Contains multiple

Quizzes

Official manual (PDF)

The first 14 lessons:

free

With access to

our trainers

Not Included

Prerequisites

There are no prerequisites for this course and exam. You don’t need to have prior knowledge of project management to understand the course.Money-Back Guarantee

We want to be sure that you’re satisfied with the course. If you’re not, you can ask for and receive a full refund for the course for up to 30 days after your purchase, while you’re in the first 30% of the course. If your purchase includes an official exam, the exam cost can be fully refunded for up to 10 days. (More information)Contents of the course

The course is designed for busy professionals; most lessons are 10 to 15 minutes long, so that you can take one or two per day, without much effort. Also, we’ve avoided homework and covered it in other ways, because you probably don’t have enough time and mental energy to spend many hours by yourself doing homework.

The course is delivered in the following sections and lessons:

01. About this course (free)

02. What is PRINCE2? (free)

03. Project timeline (free)

04. When to use PRINCE2 (free)

05. Project variables (free)

06. Project context (free)

07. Business Justification (free)

08. Stakeholders engagement (free)

09. Communications (free)

10. Lessons learned (free)

11. Monitoring and controlling (free)

12. Quality management (free)

13. Risk management (free)

14. Issues and changes (free)

15. Planning

16. Document management

17. Tailoring

People

18. Change management

19. Stakeholders and culture

20. Leading successful teams

21. Building a team

22. Communications

Business case practice

23. Purpose

24. Guidance

25. Technique

26. Principles

Organization practice

27. Purpose

28. Levels and team structure

29. Technique

30. Management products

31. Principles

Plans practice

32. Purpose

33. Types of plan

34. Stages and work packages

35. Technique

36. Product-based planning

37. Management products

38. Principles

Quality practice

39. Purpose

40. The 3 aspects

41. Management products

42. Technique

43. Principles

Risk practice

44. Purpose

45. Key concepts

46. Overall project risk

47. Cause, event, and effect

48. Risk responses

49. Planning, analysis, and control

50. Culture

51. Technique

52. Management products

53. Principles

Issues practice

54. Purpose

55. Types of issue

56. Change control

57. Technique

58. Management products

59. Principles

Progress practice

60. Purpose

61. Delegation

62. Types of control

63. Reporting

64. Escalating

65. Technique

66. Management products

67. Principles

Principles

68. Ensure continued business Justification

69. Learn from experience

70. Defined roles, responsibilities, and relationships

71. Manage by exception

72. Manage by stages

73. Focus on products

74. Tailor to suit the project

Processes

75. Starting up a project, purpose

76. Starting up a project, context

77. Initiating a project, purpose

78. Initiating a project, context

79. Directing a project, purpose

80. Directing a project, context

81. Controling a stage, purpose

82. Controling a stage, context

83. Managing product delivery, purpose

84. Managing product delivery, context

85. Managing a stage boundary, purpose

86. Managing a stage boundary, context

87. Closing a project, purpose

88. Closing a project, context

89. About the exam

Study Path

- Take the lessons:

- It’s best if you spend 15 to 30 minutes a day, every day. A gradual learning process is much more effective than an intense one. We’ve built the course with short, independent lessons to make it possible for you to study them gradually.

- While you’re learning, don’t worry about memorizing anything. If something is important, we’ll repeat it so many times from different perspectives that you will automatically remember it.

- Take notes, build mind maps, or draw diagrams while you’re taking the lessons. This helps you understand the lessons better and stay focused, even if you never use those notes.

- We’ll register you with the examination institute and send you the exam voucher. Vouchers are valid for one year.

- Now take the first simulated exam. Don’t worry if your score is not high; you still need to learn the style of the exam and how to manage your time.

- Take the second simulated exam. Find your areas of weakness and take the related lessons again.

- After a few days, take the simulated exams again to review them. At this point, you can expect scores higher than 75%.

- Now take the official sample exams. See this as a learning opportunity, and if you realize any gaps in your knowledge, go back to the related lessons and take them again.

- Using your voucher, book the date and time of your exam with the examination institute.

- Take the official exam.

- Let us know about your success! We’re always happy to receive good news :)

The guide above is our generic recommendation. If you’re in an especial situation, feel free to contact us; we can work together and recommend a custom study path to you.

FAQ

The following are the most common questions. Feel free to contact us if you can’t find the answer to your question here.It’s a self-paced online course. You can start the course whenever you want and proceed at any speed that suits you.

You’ll have unlimited access to the course for one year, and you can retake certain lessons or even the whole course if you find it necessary.

- eLearning Courses: up to 30 days, as long as you’ve not taken more than 30% of the course

- Exam Simulators: up to 30 days, as long as you’ve not taken more than one simulated exam

- Official Exams: up to 10 days

Please check the Terms and Conditions for more information.

Have questions?

Don’t hesitate to contact us if you have any questions. Your administrative and technical questions will be answered quickly by the support team, and your questions about the topics will be sent to our trainers.

To contact us, use the online chat service that is available on the bottom of the pages, send us an email to support@mplaza.training, or call us at +3228080179, +447862148245, or +1845-479-6605.

Accreditation

Management Plaza is a brand name of EMPII Group, a certified partner of AXELOS, and an accredited training organization of PM² Group, PEOPLECERT, APMG, and EXIN.

eLearning Course vs. Classroom Course

Why Management Plaza?

There are many eLearning providers, and you might be wondering which one is the best choice for you. In fact, it’s a simple decision: all you have to do is to watch demos of the courses and compare them :) Just be careful with one thing: there are some providers who create one or a few interesting videos as samples, while the rest of the course doesn’t have anything to do with that.

We are a small group of project experts who love creating content and sharing what we have learned with our peers. While this is currently our main job, earning money is not our highest priority; the highest priority is the sense of achievement we get from creating something that can really help people.

Do you need training for your company?

We can offer various eLearning packages customized for your needs.